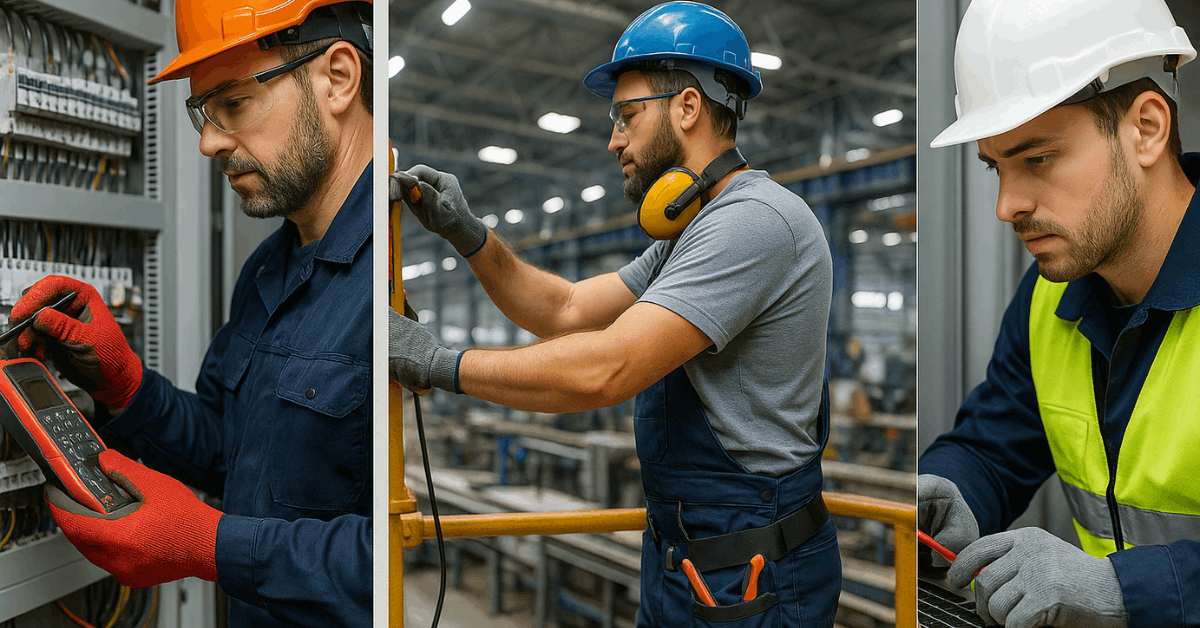

Manufacturing electrician jobs involve working on complex electrical systems that keep factories running.

These positions require strong problem-solving skills and attention to safety. If you're considering a hands-on technical career, this path can be a smart choice

What Does a Manufacturing Electrician Do?

Manufacturing electricians work in industrial settings to support production systems. They maintain and repair electrical components essential to manufacturing machinery.

You’ll often be responsible for ensuring machines operate without interruptions. The job may require quick problem-solving under pressure.

Daily Responsibilities You Should Expect

The day-to-day tasks of a manufacturing electrician can be both routine and reactive. You must be ready to inspect systems, perform preventive maintenance, and troubleshoot breakdowns.

Electricians often work on wiring motors, installing control panels, and calibrating sensors. Efficient electrical work minimizes downtime in manufacturing lines.

Skills and Technical Knowledge Required

To succeed in this field, you need a mix of mechanical and electrical knowledge. You should know how to read blueprints, operate testing equipment, and use hand tools properly.

A solid understanding of PLCs, safety protocols, and wiring techniques is essential. Strong attention to detail and problem-solving skills are necessary.

Educational Requirements

Most manufacturing electrician jobs require a high school diploma or GED. Additional vocational training in electrical technology can significantly boost your chances.

Employers prefer candidates who have completed trade school or electrical apprenticeship programs. It’s a competitive field that values practical, hands-on experience.

Licensing and Certifications That Help

Licensing requirements vary by region but often include passing a journeyman exam. Certifications such as the NCCER Electrical or OSHA 30 help you stand out.

Some employers also look for candidates familiar with the National Electrical Code. Check your state regulations for license specifics.

Typical Work Conditions in Manufacturing

Expect to work in noisy, busy factory environments. You’ll wear safety gear and may have to climb ladders or crawl into tight areas.

Shifts may rotate, including nights or weekends. You must be physically fit and alert.

Salary Expectations and Financial Benefits

Pay depends on your experience, location, and the company size. Entry-level workers earn around $50,000 annually, while senior electricians may reach $80,000 or more.

Benefits often include health insurance, overtime pay, and retirement plans. Some companies also offer bonuses or union support.

Career Growth and Advancement

You can move up to roles like Maintenance Supervisor or Controls Technician. Continuing education in automation or robotics can lead to better pay.

Management roles are possible after gaining years of experience. Certifications improve your chances of promotion.

Employers and Industry Types

Manufacturing electricians work in different sectors like automotive, food production, and electronics.

Employers include large manufacturers, local factories, and contract service providers.

Each industry has its own equipment, but core tasks remain similar. Experience in one sector often transfers well to another.

Job Outlook and Industry Demand

Skilled electricians are always in demand due to equipment complexity. As manufacturing shifts to automation, more electricians are needed to maintain those systems.

Job security is strong, especially for those who are licensed and certified. Future trends favor workers with tech skills.

Where to Find Jobs Online?

Several platforms post manufacturing electrician job openings. Use Indeed, Glassdoor, and ZipRecruiter.

Check industry-specific sites like ManufacturingJobs.com. Union boards and vocational school job centers are helpful, too.

Tips for Applying Successfully

Applying for a manufacturing electrician job means demonstrating your readiness from day one. These tips will help you present your experience and skills in the best light.

- Highlight hands-on electrical experience and any safety training you've completed on your resume.

- Emphasize measurable achievements, like boosting machine efficiency or reducing breakdowns.

- Make sure licenses, certifications, and technical qualifications are easy to find on your application.

- Practice answering technical and situational questions that test your problem-solving and on-site knowledge.

Tools You Must Be Comfortable Using

Knowing how to use the right tools makes your work faster and safer. These tools are part of your daily routine as a manufacturing electrician.

- Wire strippers are used for safely removing insulation from electrical wires.

- Voltmeters and multimeters help you test voltage, continuity, and resistance.

- Conduit benders are essential for shaping conduit to fit installation routes.

- Power drills assist with mounting electrical panels or installing fixtures.

- Circuit breaker testers let you confirm that breakers are working correctly.

- Familiarity with control panel tools and sensors enhances your accuracy when working with automation systems.

Safety Rules and Compliance Standards

Every manufacturing electrician must know how to work safely and follow required guidelines. These practices protect you and your team from avoidable hazards.

- Always follow OSHA and NFPA guidelines, along with any site-specific protocols.

- Use lockout/tagout procedures to ensure machinery is fully de-energized before starting repairs.

- Wear the correct personal protective equipment (PPE) at all times while on the job.

- Stay alert to common hazards and report any unsafe conditions immediately.

Common Challenges on the Job

This job brings real-world pressure and physical demands. Expect problems that need quick thinking and a steady hand.

- You may face urgent equipment breakdowns that require immediate attention under pressure.

- The job involves working in tight or elevated spaces, which increases physical risk.

- You must stay updated as technology, control systems, and safety protocols continue to change.

- Multitasking with accuracy is part of the daily routine and essential to avoid mistakes.

Importance of Internships or Apprenticeships

Getting real-world experience helps you stand out when applying. Internships and apprenticeships prepare you with the skills factories need.

- Hands-on training helps you build confidence and apply what you've learned in real scenarios.

- Apprenticeship programs offer supervised learning that often leads to long-term job placement.

- Internships during trade school give you exposure to actual manufacturing environments.

- Employers look for real-world experience when reviewing resumes, especially in industrial roles.

Frequently Asked Questions

You may have common questions as you consider this job. Here's a brief FAQ to address them.

- Do I need a degree to apply? No, but technical training helps.

- Can I switch from residential to manufacturing? Yes, with the right upskilling.

- Is travel required? Sometimes, especially for contract roles or large facility groups.

- Is the work physically demanding? Yes, and you need to be prepared for physical tasks and standing for long hours.

Final Thoughts: Be Ready Before You Apply

Manufacturing electrician jobs provide a stable and rewarding career in today’s industrial workforce.

These roles require technical training, proper certification, and a commitment to safety. If you're aiming for a long-term trade, this career offers real growth opportunities.